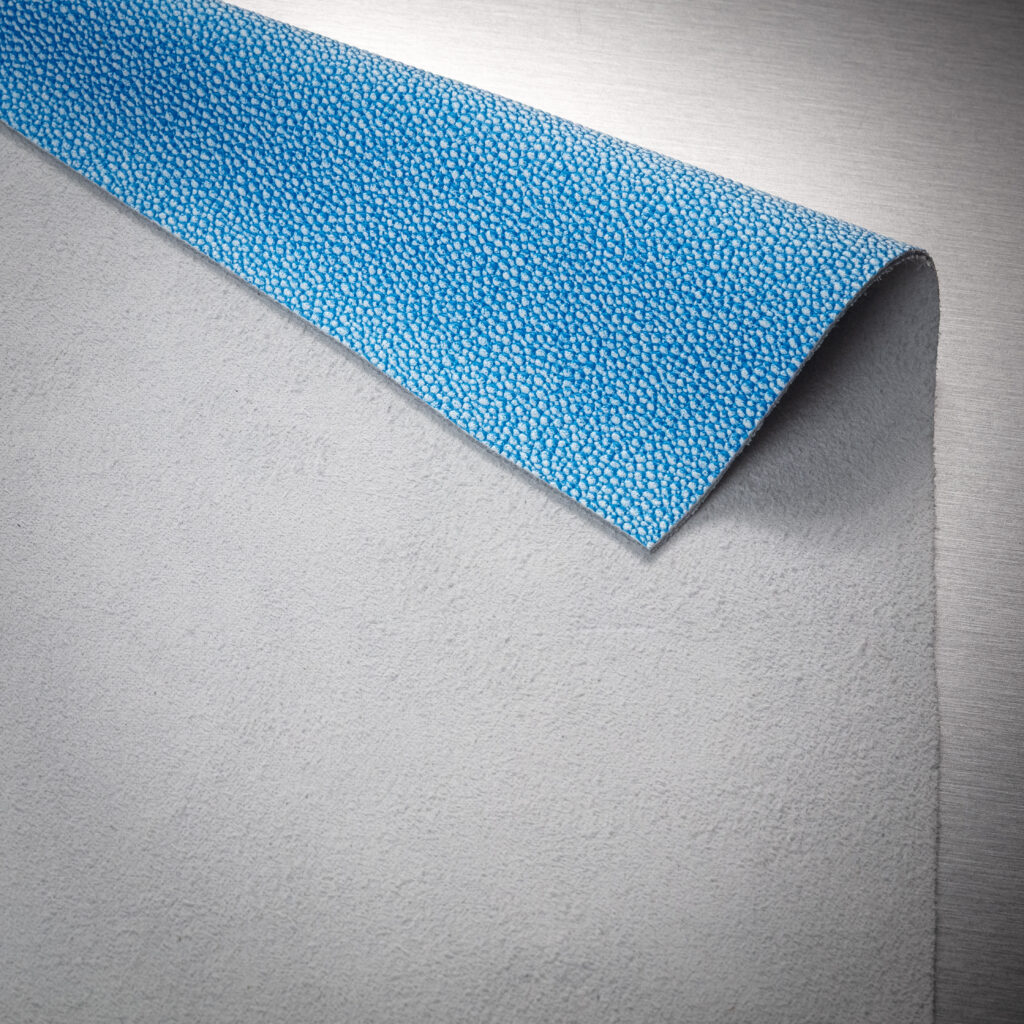

split leather

Split leather – precise processing with sustainable added value

Particularly thick leather is required for the production of split leather. The animal hide must be at least five to ten millimetres thick, which is why cowhide is often used.

Before the splitting process can begin, the hide is carefully depilated and degreased. The splitting itself usually takes place before the tanning process and requires the utmost precision. Special splitting machines are used for this, which have to be adjusted with millimetre precision depending on the thickness, condition and weight of the leather.

As early as the 18th century, special machines were developed for this work step – a technique that has stood the test of time to this day. Splitting allows at least two qualities of leather to be obtained from a single hide, which means that thicker hides in particular can be processed more efficiently.